Generator maintenance is very important to provide reliable and long life in energy production. This paper is going to enlighten the generator owner on what needs maintenance and how frequent it must be to keep the generator performing at its best.

- Importance of routine servicing: Generators are a major investment. Important for that reason, they must be maintained well in order not to fail and to increase the lifespan of service. Proper maintenance helps your generator be relied on when most needed—for instance, in case of power blackouts and emergency situations.

- Outlining the Scope of Maintenance: Generators are diverse, each with specific maintenance practices. From portable units to standby systems, being well-informed on the particular maintenance needs of your machine will save time, resources, and energy in terms of the repair that it can cause and the unscheduled downtime.

- Maintenance Frequency: Regular maintenance does not only tackle existing problems of the equipment but also includes periodic checkups and preventive steps for the manufacturer-recommended and usage-based patterns. Full inspection and servicing are recommended at least once a year or even more frequently when the generator runs continuously.

Basic Maintenance Procedures

A generator is easy to maintain, but it is an important procedure if you need it to work well and last. Regular checking, cleaning, and storage do a great deal in improving the life and usefulness of the generator.

Inspection

- Visually Inspect: At periodical intervals, visually check its external and internal parts for wear, such as cracks, rust, and the presence of oil leakage. Such symptoms are generally the first indication that something is wrong.

- Inspect Key Components: Some of the key components to monitor include the engine, fuel system, and electrical connections. Verify all hoses, belts, and electrical connections are tight without wear or corrosion.

- Check for leaks: Observe around the generator for the seepage of fluid. Oil, coolant, or fuel seepage generally can be traced to a bad seal/gasket and should be replaced to prevent this type of progressive damage.

Cleaning

- Exterior cleaning: Wipe the exterior of the generator regularly with a dry cloth. This can be used in eliminating the soil accumulated and oily stains, which cause accumulation in the engine and eventually interfere with engine cooling and operation.

- Internal Cleaning: The air filter should be cleaned occasionally because a dirty air filter reduces fuel combustion efficiency and may lead to fuel consumption. The cooling fins and other internal parts should be inspected simultaneously to ensure that there is no extraneous matter on them to prevent overheating.

- Moisture prevention: Ensure that no retained moisture may cause rusting or electrical problems once cleaned. Use compressed air on the hard-to-reach places to ensure that they are well dried out to prevent such happenings.

Storage

- Environment: Keep the generator in a cool and dry place, free from temperature and moisture fluctuations, to avoid water infiltration of assemblies or fuel, damage to metallic parts, and corrosion of electrical circuits.

- Fuel Conditioning: Store with your tank treated to prevent deterioration. Add the correct amount of fuel stabilizer to the tank before storage. Running the generator for a few minutes allows the stabilizer to circulate through the system.

- Long-Term Care: Start the generator every couple of months to ensure that lubricants run in the engine and that the battery is being charged. It will also prepare you so that you can identify potential problems that might occur during periods of non-usage.

Good generator maintenance is more than just following steps; it is detail and care. If the basic procedures that are part of maintenance are followed, you can be assured your generator is all set and reliable at your command and your very own preference.

Routine Checkups

Scheduled maintenance keeps the generator reliable and with a long life. The manual gives professional advice on routine check-ups that are vital for keeping a generator in its best shape.

-

Routine Checkups Check Engine: A thorough checkup of the engine includes: Checking the level of oil contained in the engine to ensure that there is sufficient oil to provide lubrication. Also, adhere to the schedule set by the manufacturer regarding the replacement of the oil. Check and clean the air filter of the engine to ensure that debris has not marred its performance. Check and replace the spark plug to promote the effective combustion of fuel.

- Fuel System Maintenance: A fuel system should be maintained in good performance. To have a generator ready to run, make sure that the fuel and stabilizer are fresh, to prevent degradation and to make sure it is not left idle for an extended period of time. Check the fuel lines and connections for cracks and leaking and make sure there is no problem with fuel delivery.

- Battery maintenance: A well-maintained battery will ensure your generator starts when needed. Keep the battery charged and the terminals clean in order to prevent corrosion, which will negatively affect the connectivity in a battery and shorten its life.

Adherence to the truths will see your generator being efficient and reliable. Periodic check-ups will not only ensure that your generator is useful for a long time, but also that it is active and efficient whenever you need it most. Be proactive in your routines of maintaining it to avoid surprise failures, and costly repairs.

Troubleshooting Common Issues

Certainly, good operation and effective troubleshooting call for regular maintenance of your generator. This guide outlines actual steps to take regarding common problems in order to make your equipment work better and last longer.

Start-up Failures

Several reasons your generator may fail to start include:

- Fuel Issues: Ensure your fuel petcock is on and the gas is fresh.

- Battery Problems: The battery should have a full charge, and the connections should be tight.

- Oil Levels: Lack of enough oil could lead to the failure of the generator to start up. You need to ensure that the oil level is okay and that you refill in case of any shortages.

Power Output Problems

If your generator isn’t producing the right amount of power:

- Overload: Confirm that the load does not exceed the generator’s capacity.

- Maintenance Requirements: Examine the air filter and exhaust system for blockages that could impair power output.

Noise and Vibrations

Unusual noises or vibrations most often indicate mechanical problems:

- Loose Components: Tighten all joints and fastenings, including nuts, bolts, or belts.

- Component Degradation: Maintained parts, like bearings and couplings, are subject to wear. If such parts show wear, consider a replacement.

In a nutshell, proper maintenance and addressing issues promptly ensure that your generator remains reliable as a power source. Continuous care helps avoid major issues, extends the equipment’s lifespan, and offers reliability and security when most needed.

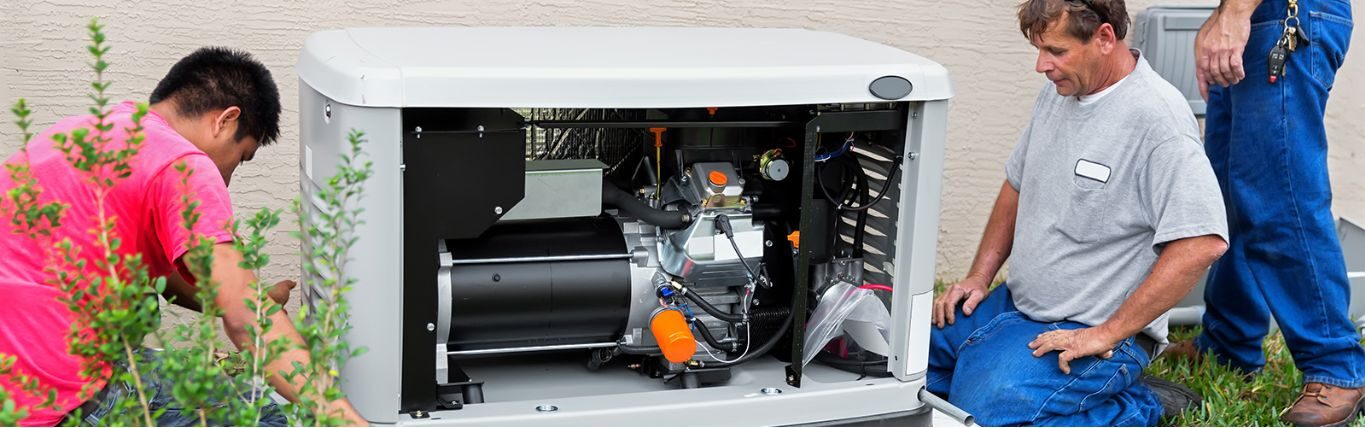

Professional Servicing

You will need service by professionals to ensure the long life and dependability of your generator. This overview will help you learn when professional help is needed, how to choose a competent service provider, and how to handle the cost of maintenance.

Recognizing the Need for Professional Servicing

You need to identify the signs that your generator requires professional servicing:

- Persistent Problems: If routine troubleshooting fails to fix the issues.

- Advanced Repairs: For complications involving the engine’s electrical system or internal components.

- Specialized Maintenance: For tasks that require specific tools or expertise, such as engine calibration or performance testing.

Selecting a Professional Service Provider

Choosing a suitable professional service provider requires consideration of several factors:

- Certifications: If general troubleshooting won’t fix the issues.

- Experience: Usually for malfunctions in the engine electrical parts or internal parts.

- Reputation: To diagnose peculiarities that need special tools or skills like engine tuning or testing.

Planning Maintenance Costs

With good budgeting in place, professional maintenance remains: Improved agreements:

- Maintenance Agreements: This may involve the pursuit of service agreements, including routine maintenance and repair when there is a need to do so.

- Competitive Bidding: Ensure that you get them from at least more than one service provider so that you are not overpriced.

- Preventive Maintenance: Regular maintenance can keep you from expensive repairs in the future.

In general, the whole process of maintaining the generator depends on professional servicing. Knowing when to hire professional help, choosing the right service provider, and budgeting for the costs of maintaining your generator are important in ensuring that your generator is in the best working condition to be called upon.

Generator Maintenance for Mobile Detailing

Mobile detailing generators have to deal with a lot of unique issues because they are always subjected to transportation in literally all kinds of working conditions. This guide details special maintenance that should be done to make sure your generator is still efficient and reliable.

Specific Requirements

In mobile detailing, generators are exposed to a much higher stress than stationary models. With changes in the environment and the constant motion of the unit, one may find the necessity for more frequent maintenance, including oil changes, air filter replacement, and routine inspection.

Maintenance on the Move

- Regular Monitoring: Regularly check the oil level and air filters every break.

- Necessary Tools: Basic tools to bring for quick fixes and adjustments.

Efficiency Strategies

- Consistent Calibration: Keep your generator calibrated only to create the necessary power for your equipment.

- Intelligent Usage: Make sure to run the generator on a load that the engine is rated for so that it won’t get overloaded, leading to wear and maintaining a wear-free load.

Designed with service and repair strategies for your mobile detailing business in mind, your generator will stay viable, and you will, too, have the ability to continue your work in any location. Good maintenance practices will keep you busy without any hitches.

See more at Best Generator For Mobile Detailing

Conclusion

It would be great to pursue a structured plan for generator maintenance. It is just a level deep from the steps enumerated by stressing the importance of every process. In so doing, you can rest assured that your generator will be in perfect working order and ready for use anytime. Most of the time, apart from successfully extending the generator’s life span, it also helps ensure that the generator works more effectively and becomes more reliable in an emergency, allowing a worry-free and stable time of need.

[…] See more at Generator Maintenance […]

[…] See more about Generator Maintenance […]

[…] Read more about Generator Maintenance […]

[…] See more about Generator Maintenance […]

[…] See more at Proper Generator Maintenance Tips […]

[…] See more at Proper Generator Maintenance Tips […]

[…] See more about Proper Generator Maintenance Tips […]