The Importance of Fuel Gauges

A fuel gauge is an easy functional tool but encompasses such great importance, serving as a lifeblood in the operational management of any fuel-driven machine. Knowledge of remaining fuel in a tank is therefore very important, considering preventive measures against running out of fuel when least expected, as may be called for in the case of needed power generation or traveling very long distances in times of need. Moreover, it could help diagnose problems, provide accurate gauge readings on the fuel consumption pattern, ensure periodic maintenance, and optimize fuel usage to save costs and lessen environmental impacts.

How Fuel Gauges Work

Fuel gauges are based on one of several common principles, the first of which is a float-type mechanism. For this system, as the level of the fuel changes, a float resting on the top of the fuel moves a resistance arm. That resistance is then applied to an electrical signal, which by way of a gauge on the dash or control panel, shows the fuel level visually.

Digital gauges are electronic sensors that are slowly becoming common in modern equipment for the measurement of fuel levels. These give an even more precise readout and are able to interface with the management system of a vehicle or piece of equipment, thereby providing detailed data on the consumption and efficiency of fuel.

Best Practices for Reading Fuel Gauges

- Regular Checks: Always check the fuel gauge, especially before starting out on a long trip or engaging in activities that may require the machine to be used for many hours. Develop the habit of never getting caught off guard by fuel shortages, and this is going to help in planning when to make stops to refuel or have maintenance carried out.

- Understand Gauge Positioning: The positioning of the vehicle or equipment may sometimes alter the readings given by certain gauges. For instance, a slope can throw the reading off. So, one should always check the gauge on a level surface for the most accurate reading.

- Low Fuel Awareness: One will observe the low fuel warning light or indicator, which is automatic for most vehicles and generators. Refilling at the earliest instance that the indicator lights up ensures continuity of operation and that the fuel pump and the engine run smoothly, since running a tank dry sometimes leads to damage.

Tips for Using Fuel Gauges in Different Equipment

- Car: The most common vehicle fuel gauge. All drivers should know that refilling the gauge may take a few moments before it reflects the reading. Re-fueled vehicles should not be run with low fuel, as sediment in tanks can be drawn into the engine or fuel lines and cause blockage or wear.

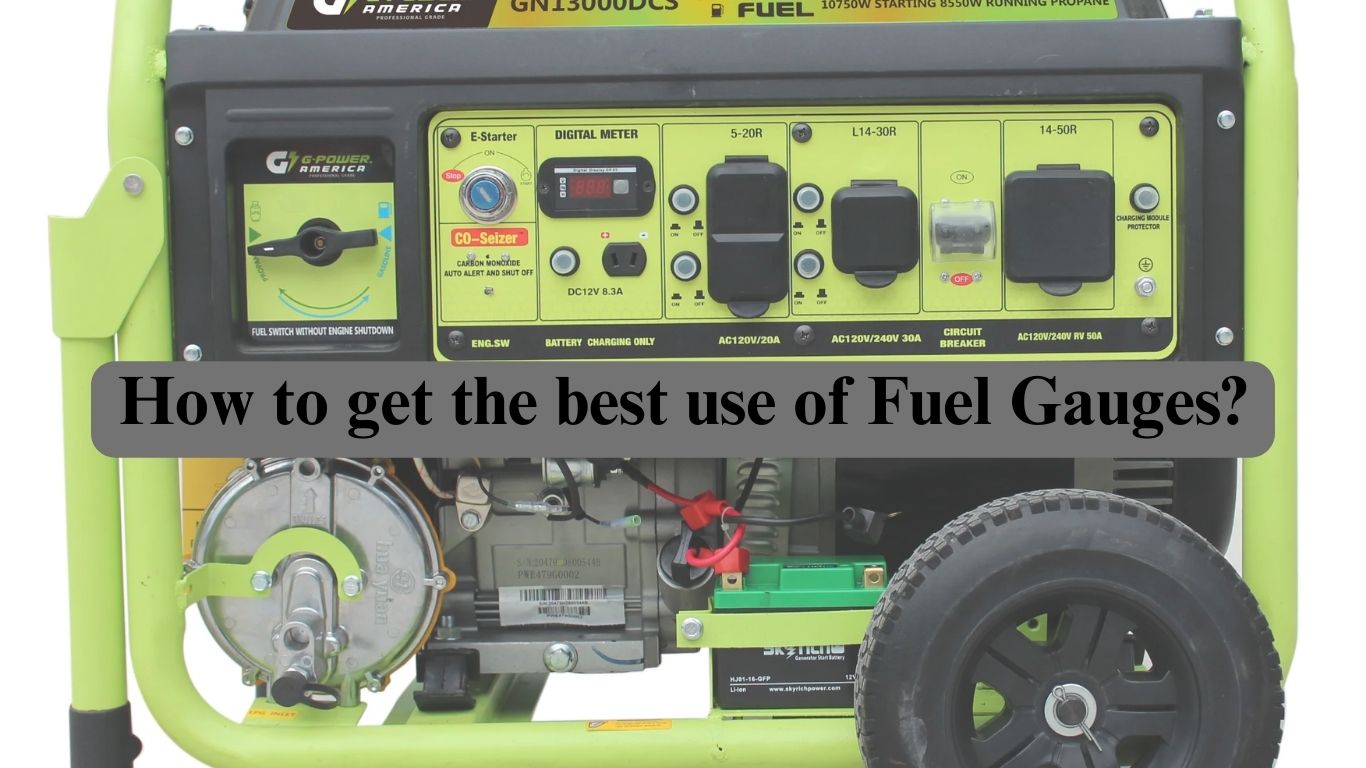

- Generators: The monitoring of fuel gauge readings should be done continuously for generators, especially those meant for sensitive critical applications such as hospitals or data centers. Clearly, a majority of the generators work at steady high loads, and given this condition, they consistently consume fuel. It is possible to make a better prediction regarding the need for refueling when it will be required with such trends in fuel consumption.

- Boats: It is important to note that the gauges on these vessels operate at various angles whilst in continuous motion. Normal recalibrations of the gauge can help in retaining the accuracy of the gauge in use. The sloshing and motion of a gauge are not precise, so boaters should always carry extra fuel.

Advanced Uses of Fuel Gauges

Follow up these enhancements and recommendations for fuel gauges advanced applications in generators:

- Data Logging: Choose fuel gauges that can be logged over a certain period of time, so that the fuel use pattern can be observed for improved predictability of efficiency.

- Interface with Management Systems: This means it links your fuel gauge with the generator’s management systems. These linkages can be monitored remotely, and alerts can be transmitted to report low levels.

- Predictive Maintenance: Be more forward-thinking with your fuel gauge data to predict what can go wrong in the future. Use historical data and consumption rates from the past to build reliability into your generator.

These are advanced strategies that make your generator’s fuel gauge so much more useful for the systems to run near peak efficiency and maximize fuel economy.

Conclusion

Fuel gauges are important in the working life of any fuel-powered machine, bearing in mind that with it comes some fundamental information relevant to energy management, maintenance, and operating readiness. From a car to a boat or even to a standby generator, the practice of using fuel gauges and the best ways to get a correct reading has greatly benefitted their good operational reliability and cost-save. Properly practicing good checks and maintenance will help assure the user that all of their equipment is running at the best efficiency, providing reliable service and operational sustainability in fuel use.

Read more: Best Generator For Mobile Detailing